Products

Steaming and Cooling Processes

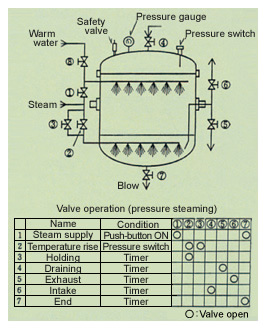

Steaming Vessel

Some conventional steaming methods were only based on hunch and intuition. This unit does not depend on any such methods. The steam is blown in, the temperature is raised, the pressure is maintained, the hot water is drained, the water is sprinkled, and the air is ventilated. All these steps are automated. This unit makes it quick to complete the steaming process and the discharging process.

Features

- (1) The predefined program manages the steaming process, which ensures uniform quality.

- (2) You can freely define the program to process steaming, steaming water sprinkling, water boiling, and so forth.

- (3) An automatic operation is performed according to the program of your definition.

- (4) The lid is of a clutch door type. It can be removed easily.

- (5) The lid can be opened fully for easy cleaning.

Specification

| Capacity (kg) | Size (ø, H) |

Total volume (m3) |

Volume on drainboard (m3) |

Max. operating pressure (kg/cm2) |

Motor (kW) |

|---|---|---|---|---|---|

| 1,000 | 2,000 x 1,400 | 5.8 | 4.1 | 2.0 | 2.2 |

| 1,500 | 2,200 x 1,800 | 8.9 | 6.6 | 2.0 | 3.7 |

| 2,000 | 2,500 x 1,800 | 11.3 | 8.3 | 2.0 | 5.5 |

| 2,400 | 2,600 x 2,050 | 13.8 | 10.3 | 2.0 | 5.5 |

NAGATA BREWING MACHINERY

TEL:078-995-4700

2-1-1 Mitsugaoka, Nishi-ku, Kobe 651-2228