Products

Seeding Process

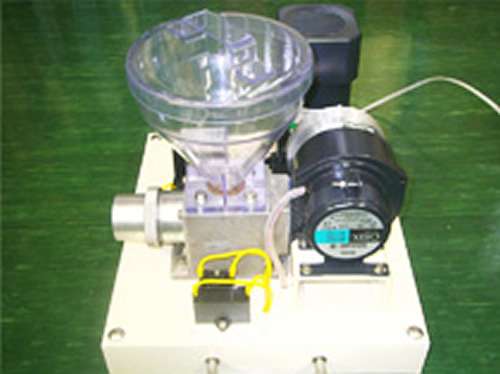

Seed Koji Sprinkler

Nagata's special sprinkling method changes a complicated manual labor into a highly systematized working process. You can freely define a fixed amount of sprinkles and make a fine adjustment of the amount. Therefore, you can not only save labor but also enhance the cost performance.

Features

- Uniform, adjustable automatic sprinkling is realized.

- The seed koji sprinkling process is automated. A predetermined amount of seed koji can be sprinkled evenly. In addition, you can make a fine adjustment of the amount of the sprinkled seed koji. The seed koji will never be insufficiently sprinkled or wasted. You can add any amount of seed koji.

- Sprinkling at a constant temperature under constant air-dry conditions

- The air passes through the air dryer unit before blowing on the rice. In addition, an electric heater is mounted at the intake port of the air blow fan. Therefore, the seed koji can be sprinkled at a constant temperature under constant air-dry conditions.

- Bridge prevention

- The inside surface of the hopper is Teflon-coated, and an electric heater is attached around the outside surface. Thus, the temperature of the hopper is controlled to prevent a bridge that may be caused by moisture.

* The hopper can hold about 4 kg of seed koji. - Easily attached to the hose

- The exit of the sprinkler is connected to a VS hose using a sanitary clamp, which allows easy removal. The hose is 3 to 4 meter long. You can use the sprinkler away from the koji mixer conveyor.

- Very clean

- The outer surface is covered with stainless steel (SUS304), while the inner air piping has a sanitary structure. These features ensure a high level of hygine.

NAGATA BREWING MACHINERY

TEL:078-995-4700

2-1-1 Mitsugaoka, Nishi-ku, Kobe 651-2228