Products

Koji-making Process

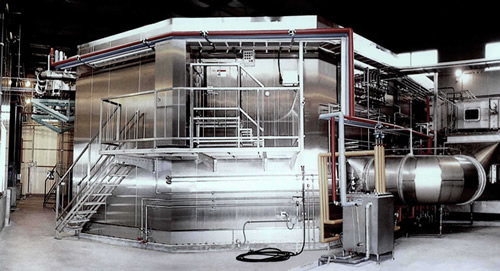

NFT Automatic Koji-making Machine

Among the entire brew processes, the koji mold making process is a very important step. The quality grade of the koji mold greatly affects the product. The research and development for this machine are based on the techniques of the traditional koji making. The koji mold is made in the most optimal environment according to the characteristics of sake koji, shoyu koji, miso koji, and so forth. All the steps from loading and mixing to koji discharging are automated. This automatic koji mold making machine saves labor and provides high quality koji mold.

Air Conditioner

When making sake koji, shoyu koji, and miso koji, you need specific management methods to make each type of koji mold depending on the differences of materials, preparation, and fermentation management. We have a wide variety of air conditioners to incubate koji in an optimal environment according to the characteristics of each koji mold.

- Air conditioner for brewing sake, shochu and miso

- Our air conditioners enable you to incubate koji mold in the most optimal temperature and humidity. You can obtain high grade koji mold, sohaze or tsukihaze, in accordance with your needs.

- Air conditioner for brewing shoyu

- This unit makes use of fresh air for humidification. Therefore, its running cost can be reduced drastically. Thick layer deposition upon incubation (250 to 600 mm) is possible, reducing installation space and cost.

Specification

For brewing sake

| Capacity /cycle (kg) |

Disk diameter (mm) | Layer thickness (mm) | Air conditioner (kW) | Cultivation unit (kW) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Room temperature control | Product temperature control | Cooling water pump | Heater | Disk | Screw | Mixing device | Cleaning | ||||

| Aging | 1,000 | 3,000 | 300 | - | 1.5 | - | - | 1.5 | 1.5 | 2.2 | - |

| 1,500 | 3,500 | 300 | - | 1.5 | - | - | 1.5 | 1.5 | 2.2 | - | |

| 2,000 | 4,000 | 300 | - | 1.5 | - | - | 1.5 | 1.5 | 2.2 | - | |

| 2,400 | 4,500 | 300 | - | 2.2 | - | - | 1.5 | 1.5 | 2.2 | - | |

| 3,000 | 5,000 | 300 | - | 2.2 | - | - | 1.5 | 1.5 | 2.2 | - | |

| Koji-mold making | 1,000 | 4,000 | 150 | 0.75 | 1.5 | 0.75 | 4.0 | 1.5 | 1.5 | 2.2 | 3.7 |

| 1,500 | 5,000 | 150 | 0.75 | 2.2 | 0.75 | 5.0 | 1.5 | 1.5 | 2.2 | 3.7 | |

| 2,000 | 5,800 | 150 | 1.5 | 2.2 | 0.75 | 5.0 | 1.5 | 1.5 | 2.2 | 3.7 | |

| 2,400 | 6,400 | 150 | 1.5 | 2.2 | 0.75 | 5.0 | 1.5 | 1.5 | 2.2 | 3.7 | |

| 3,000 | 7,000 | 150 | 1.5 | 3.7 | 1.5 | 7.0 | 1.5 | 1.5 | 2.2 | 3.7 | |

For brewing shoyu

| Capacity /cycle (kg) |

Disk diameter (mm) | Layer thickness (mm) | Air conditioner (kW) | Cultivation unit (kW) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Blower | One-fluid humidification | Two-fluid humidification | Chiller | Disk | Screw | Mixing device | Cleaning | |||

| 3,200 | 6,500 | 250 | 15 | 1.5 | 0.2 , 5.5 | 30 | 2.2 | 2.2 | 3.7 | 3.7 |

| 4,800 | 8,000 | 250 | 15 | 1.5 | 0.4 , 7.5 | 37 | 2.2 | 2.2 | 3.7 | 5.5 |

| 6,000 | 8,500 | 250 | 22 | 2.2 | 0.4 , 7.5 | 37 | 2.2 | 3.7 | 3.7 | 5.5 |

| 6,100 | 9,000 | 250 | 30 | 2.2 | 0.4 , 7.5 | 45 | 3.7 | 3.7 | 5.5 | 5.5 |

| 8,400 | 10,500 | 250 | 30 | 2.2 | 0.4 , 11 | 65 | 3.7 | 3.7 | 5.5 | 5.5 |

| 12,000 | 12,500 | 250 | 37 | 2.2 | 0.75 , 15 | 37 | 3.7 | 3.7 | 5.5 | 5.5 |

For brewing miso

| Capacity/ cycle (kg) |

Disk diameter (mm) | Layer thickness (mm) | Air conditioner (kW) | Cultivation unit (kW) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Blower | One-fluid humidification | Two-fluid humidification | Chiller | Disk | Screw | Mixing device | Cleaning | |||

| 2,000 | 4,500 | 250 | 5.5 | 1.5 | 0.2 , 0.75 | - | 1.5 | 1.5 | 2.2 | 3.7 |

| 3,000 | 5,600 | 250 | 11 | 1.5 | 0.2 , 0.75 | - | 1.5 | 1.5 | 2.2 | 3.7 |

| 5,000 | 7,000 | 250 | 15 | 1.5 | 0.2 , 1.5 | - | 2.2 | 2.2 | 3.7 | 3.7 |

| 10,000 | 10,000 | 250 | 30 | 2.2 | 0.4 , 3.7 | - | 3.7 | 3.7 | 5.5 | 5.5 |

| 15,000 | 12,500 | 250 | 37 | 2.2 | 0.4 , 3.7 | - | 3.7 | 3.7 | 5.5 | 5.5 |

Please consult us for products with specifications other than those listed above.

Note that the layer thickness will be 250 mm to 600 mm.

NAGATA BREWING MACHINERY

TEL:078-995-4700

2-1-1 Mitsugaoka, Nishi-ku, Kobe 651-2228