Products

Washed Rice Conveying Process

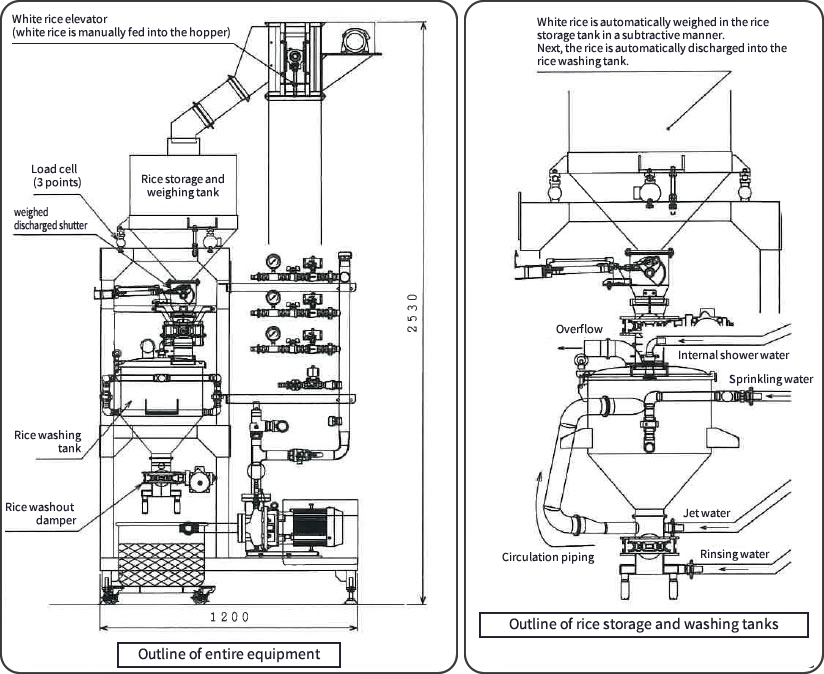

Automatic Weighing and Washing Machine

Realizing batch-type, high-quality rice washing to produce highly polished rice.

In the past, many people worked in this process while watching a timer, which required a lot of labor.

The Automatic Weighing and Washing Machine can automatically perform rice storage weighing, small lot weighing and dispensing, convection circulation washing, and shower rinsing by simply feeding white rice into the hopper of the elevator on a regular basis.

The operation flow begins with loading white rice into the rice storage tank by the elevator. The process is followed by load-cell weighing control, discharge after weighing, convection circulation washing, washed rice discharging, washing inside the equipment, and final shower rinsing in the rice washing colander.

Next, the rice washing colander is manually taken to the next process. The Vacuum Dehydrator (sold separately) can drain rice more completely after washing.

The weighing value of white rice and the time for washing, rinsing, and equipment cleaning can be set on the touch panel on the operation console, allowing customers to use the system under conditions that meet their needs.

Furthermore, considering the washability and sanitation of the system, cleaning water is flushed after each rice batch to keep the equipment clean.

The Automatic Weighing and Washing Machine will contribute to labor-saving, higher accuracy, and improved certainty in the delicate and diligent process of washing small lots of highly polished rice.

Features

- More reliable and delicate rice washing

- • Reliable rice cleaning by convection circulation washing and rinsing

• Reliable rice washing by the overflow system - Ensuring high factory working accuracy

- • Reliable weighing control with load cells

• Easy control and settings with the touch panel

- High equipment cleanability

- • Cleaning inside the machine for each batch by jet water and an internal shower

• Sanitary structure for easy cleaning

• Main unit and piping all made of stainless steel for high cleanliness

Equipment overview

Specifications

| Performance | External dimensions |

|---|---|

| 350 kg/h max. | W1520mm X D1200mm X H2530mm |

* The primary water supply (connection by hose or piping to the pump attached to the equipment) is not included.

* The primary power supply (200 V power connection to the operation console attached to the equipment) is required separately.

* The dehydrator is sold separately.

NAGATA BREWING MACHINERY

TEL:078-995-4700

2-1-1 Mitsugaoka, Nishi-ku, Kobe 651-2228