Products

Seeding Process

Sanitary Seed Koji SprinklerImproved water resistance with one-touch disassembly for sanitation.

This equipment renews the time-proven, micro-adjustment-type Seed Koji Sprinkler with consideration of ease of use.

Diverse types of seed koji need to be used in response to diverse types of koji (malted grain) production.

The conventional equipment has been improved to collect the residues of seed koji after each brewing and completely remove and clean the seed koji attached to the hopper and screw.

The product has an improved structure that allows one-touch disassembly without using tools, shortening the cleaning time and improving sanitation.

We have increased the low-speed range and made it possible to sprinkle smaller amounts than before. Furthermore, the setting method has been changed from analog to digital. The supply capacity can be measured numerically. This function ensures the reproducibility of the same sprinkling volume every time, even if an operating worker changes.

In addition, we have enhanced the waterproof and dustproof performance to protect against unintentional splashing water, dust, and foreign objects, so that the product can be controlled with peace of mind.

Features

- One-touch disassembly for complete cleaning

- • All parts that come in contact with seed koji can be disassembled without using tools.

• The upper hopper and bridge prevention vane can be disassembled. - Expanding the adjustment range of the volume of seed koji mold sprinkled

- • The sprinkling volume can be set digitally, eliminating the need for adjustments each time.

• Expanded low-speed range to achieve smaller amounts of seed koji mold powder. - Enhanced water and dust resistance

- • Waterproof cover on digital panel (protection class IP64)

• Wire-through connector (protection class IP68)

- Compactness and weight reduction

- • All electronic components are placed inside the case, making the main body smaller.

• A reduced number of parts is used for product maintenance ease and weight reduction.

Equipment overview

Specifications

| Application | Sprinkling a constant volume of seed koji mold (powder) |

|---|---|

| Main materials | Hopper: Transparent vinyl chloride Upper body block: Aluminum (AC7A) Screw shaft: Stainless steel (SUS304) Casing: Stainless steel (SUS304) |

| Hopper capacity | Approximately 1.4 liters |

| Power supply | 100 VAC (single phase) |

| Power consumption | Fan: 32 W (60 Hz) Screw rotation: 60 W (60 Hz) |

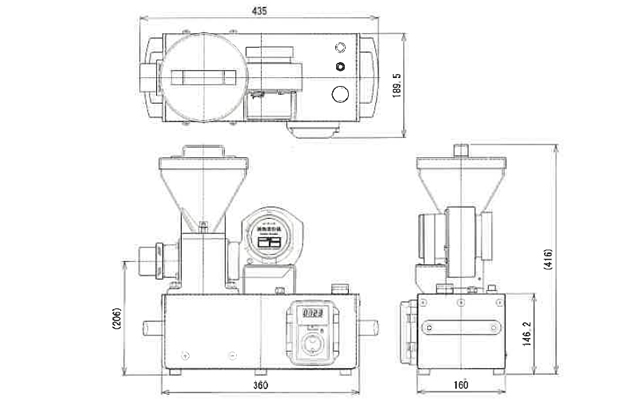

| External dimensions | 190 × 435 × 416 mm (W × L × H) |

| Weight | 10.4 kg (with no load) |

NAGATA BREWING MACHINERY

TEL:078-995-4700

2-1-1 Mitsugaoka, Nishi-ku, Kobe 651-2228